The jet filters are automatic systems allowing to take dust, odour and smoke arising during production in an industrial area, from environment and to filter them.

Dusts arising during transportation of bulk materials in dust, granular and grain structure from one point to another, storing them and processing them, harm the environment. Dedusting and filter systems are used to collect these dusts before they spread to the environment.

Dusty air, according to the status of the system during transferring bulk raw materials through mechanic of pneumatic carriage systems, is moved to the filter by pressure or vacuum method. Dust particles entering the jet filter are retained by the cartridge filter or sack filter elements inside. Air separated from dust particles is discharged through filter elements. With the reverse pressurised air jet system, dust material adhering on the cartridge filters is automatically cleaned. Dusty materials cleaned from the filter elements are sent back to the process or stored in a separate bunker. The air jet system consists of pulse valves, compressed air tank, air injectors and electronic control board.

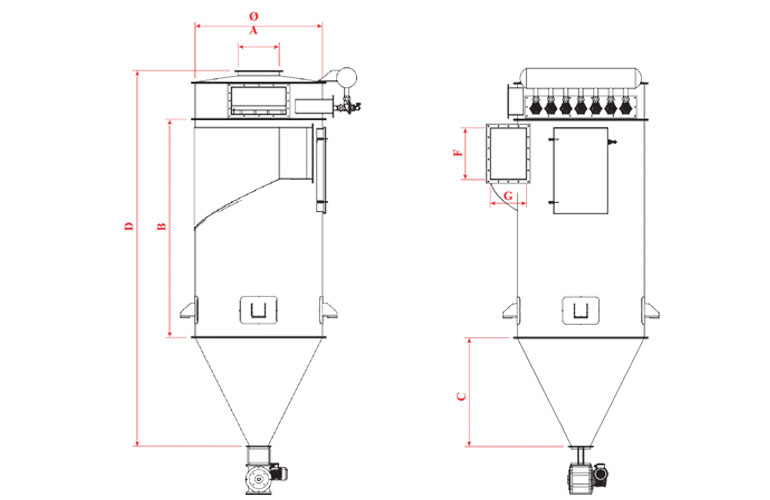

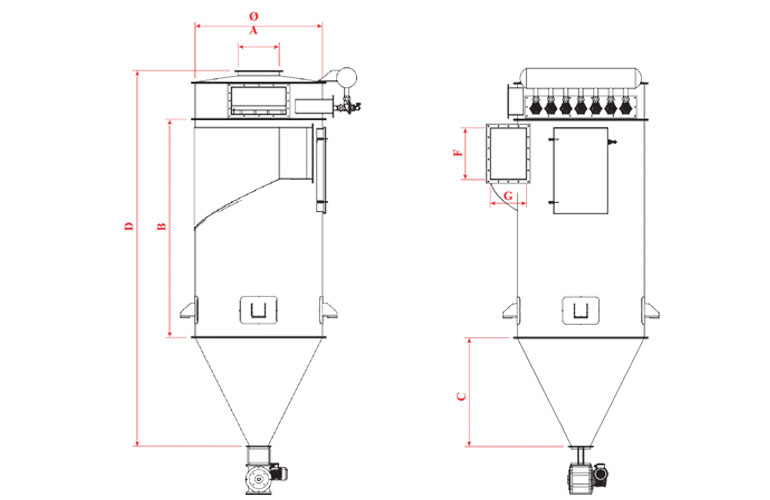

MACHINE TECHNICAL DRAWING